Cost Conundrum: Standard Costing for Manufacturers

A manufacturer must know the cost to make its product. Seems logical. Unfortunately, many manufacturing leaders claim they don’t know their costs to the extent they desire. The simple reason is that tracking standard costs is a complex and resource-intensive exercise. Most manufacturers resort to a standard costing system.

A standard costing system is a management accounting method used to plan, control, and analyze product costs. It involves setting predetermined, standardized costs for various cost elements (such as materials, labor, and overhead) and then comparing these standard costs to the actual costs incurred during production.

How do manufacturers use standard cost?

Applications for a standard cost system are many, but primarily are used to:

- Value the cost of inventory and cost of production.

- Budget and forecast for company operations.

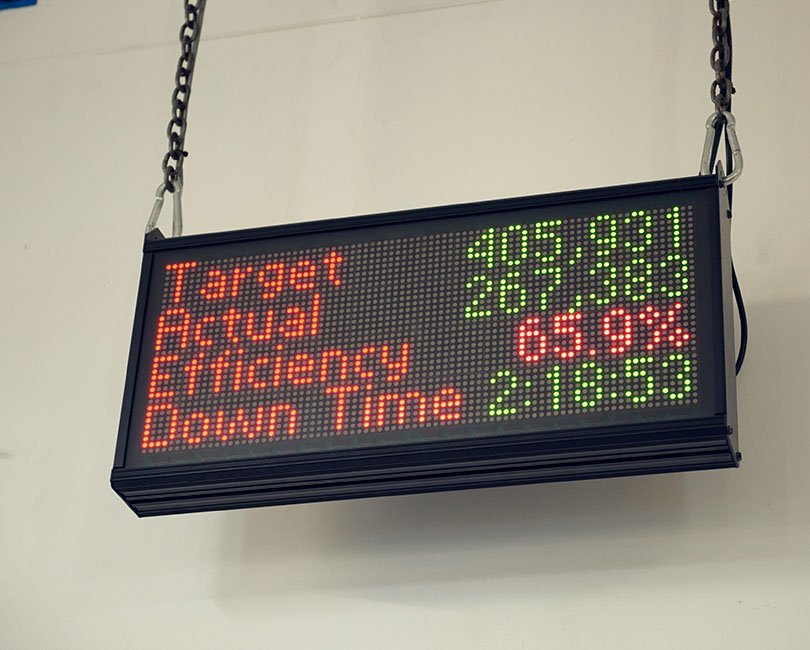

- Monitor and control labor and material use efficiency in the manufacturing process.

- Price product appropriately.

Why do so many manufacturers struggle with standard cost systems?

Utilizing a standard cost system is complex and requires resources, employee discipline, and maintenance. Establishing a standard cost for each product takes time but might be the most straightforward task. More challenging is the job of tracking the actual costs of each product. However, in tracking actual costs, management should invest more time.

Capturing the actual cost of each product unit and comparing it to the standard is where management yields critical, profit-improving information. In the analysis of variances, management determines if the price is correct, if there are opportunities for productivity to be explored, and if there are avenues to reduce material costs.

Complexity

If every manufacturer made only one product, with consistent demand, flat wages, and flat material prices, comparing standard cost vs. actual cost would be a breeze. But this is the real world…most businesses have significant variability in staffing, labor wages, material cost, and demand. Most companies make several different products with wildly different prices and time to produce, but which run through the same manufacturing process. A high number of variables = high complexity.

Resources

A proper standard cost system requires operating software to capture actual costs (typically an ERP system). A typical ERP system can be a $100k investment to implement and maintain over a few years. Many businesses lack the cash flow to support that investment and choose to rely on Quickbooks or a financial-focused platform that does not adequately capture the data required to track the actual cost to produce an individual item. Maintenance of an ERP system requires significant time and energy from accounting, operations, and engineering. Many manufacturers do not have the capacity available to set aside time from these departments.

Employee Discipline

An organization must be disciplined to track individual product/item costs. Employees on the shop floor are required to input their time and associate it with units of production. Also, employees must honor the process by which materials are assigned to an item they are working to complete. It seems simple, but humans vary in the dedication it takes to be consistent.

Maintenance

A robust standard cost system involves updating labor rates, material costs by item, variance analysis, and communication of findings. In a mature organization of size, that duty typically rests with a Cost Accountant. Most small to mid-size businesses do not have the resources to fund a dedicated Cost Accountant. Therefore, it falls to another person as a part-time responsibility. As one can imagine, the standard cost system maintenance takes a back seat in a part-time focus.

Next Steps

In today’s ever-evolving manufacturing landscape, operational efficiency is not just a goal; it’s a necessity. The road to mastering a standard cost system may appear challenging, but it’s not a path you must walk alone. Collaboration is key to overcoming the common obstacles associated with standard costing. By working alongside your current ERP provider and engaging with experienced outsourced accounting experts who intimately understand how to harness your system’s and data’s full potential, you can confidently navigate the challenges.

Your journey to enhanced efficiency and profitability begins with a simple step – contact me, Mike Benjamin, to start the conversation.