The Future of Manufacturing: Data-Driven Business Intelligence

In a recent PwC survey, 68% of CFOs say “they plan to accelerate digital transformation using data analytics, AI, automation and cloud solutions.”

Looking back to a CFO survey in 2017, you’ll see the same priorities were true. But has anybody made progress? What makes some businesses succeed with data transformation over others?

As a fractional CFO for many companies over the past years, I’ve observed only a few company CEOs commit to data analytics and use it to improve company performance. From those experiences, I’ve identified three key commonalities that contributed to their success.

Look Beyond Financial Data Analysis

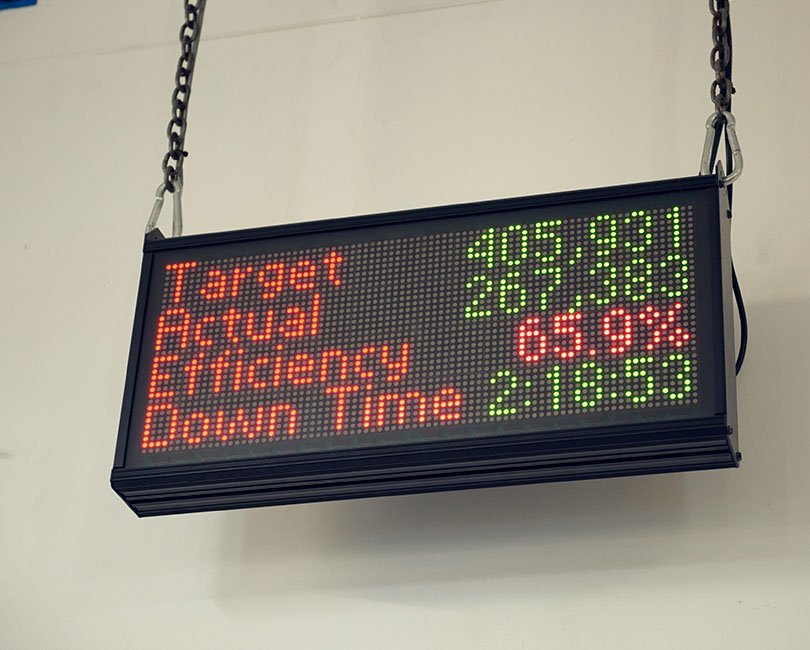

As a CFO, of course, I value financial results. So it might sound like a contradiction to prioritize non-financial data. My observations are that all companies have financial reporting; it’s a matter of the frequency of publication and details, but few companies have routine visibility of the non-financial data. This non-financial data can significantly impact a business’s financials. The best CEOs see the value in timely non-financial reporting, including manufacturing efficiency, scheduling, customer management, quality, and purchasing. Those CEOs review gross margins and net income monthly but focus on manufacturing efficiency reporting daily.

Let’s face it, financial information is essential, but it looks through the rearview mirror. Daily reporting on manufacturing efficiency and quality metrics allows a business to look forward and can result in decisions that change the financial outcome for the month and beyond. Given a choice, most companies should choose metrics that help them make better business decisions every day.

Build Dashboards & Key Performance Indicators (KPI)

Most manufacturers operate using an ERP system. With few industry-specific platforms, manufacturers use many different systems. Every ERP system varies in functionality, ease of use, and reporting capabilities relative to the data CEOs seek to drive their company. Yet all manufacturing CEOs need essentially the same information to lead their companies. The value of business intelligence (BI) tools is the ability to mine data from disparate sources and combine it into usable information through dashboards, reports, and key performance indicators (KPIs).

The most successful companies I’ve worked with use BI tools to get timely information on scrap, variance in labor utilization, scheduling, etc., to help change performance as it’s happening. For example, one client noticed a rise in rework was causing labor and material overages.

That CEO led an effort to pull information from their ERP system and couple it with a unique field in a BI tool to categorize factory rework into root cause buckets. Ultimately it was discovered that some standard practices in one work center impacted rework in another work center. Making the data visible through dashboards and monitoring results across the factory significantly reduced rework costs. This data did not exist independently in the ERP or financial systems.

Drive Data Usage from C-Suite to the Factory Floor

Once the reporting tools have been developed, and the proper data is in management’s hands, the journey to performance has started. In a fast-paced world, leaders may be tempted to move on to a new initiative and rely on mid-level management to take it from there, leading to a lack of progress and frustration.

The most successful companies take significant time after tool development to drive data usage into their organization via weekly (or more frequent) huddles. This stage is often the most tedious and painful part of the journey but also the most important. It involves C-Suite questioning their managers about the data using various root cause analysis tools (ex. “5 Whys“).

Some found that their culture was not structured to carry out the changes necessary to use the tools and leveraged outside consultants and programs to help build the right cadence and culture.

The bottom line is that the most successful manufacturers are the ones who show unwavering commitment to building a data-focused culture. These businesses spend ample time discussing data, reviewing dashboards, and meeting with their factory staff and management to hold each other accountable.

Next Steps

Leveraging data can be a game changer for manufacturers who want to drive growth. Please watch our On-Demand Webinar recording: Town Hall, Why CEOs and CFOs Should Turn Big Data into Financial Action. Panelists include a CEO who drove over $2 million of profit through a manufacturing dashboard and the BI company that helped build the tools.